+ Crude Palm Oil (CPO)

+ Palm Oil Mill Effluent (POME)

+ High Acid Crude Palm Oil (HACPO)

+ Used Cooking Oil (UCO)

+ Palm Oil Mill Effluent (POME)

+ High Acid Crude Palm Oil (HACPO)

+ Used Cooking Oil (UCO)

We cannot stop the world consuming millions of tons of edible products as well as soap, detergent, cosmetics, toiletry products, pharmaceuticals and a whole host of industrial products even including lubrication oil. What we can think about is innovative ways to produce high quality and affordable goods and Palm Oil is certainly something we can turn to. In fact, it is already being used in many products and a lot of people are probably not aware of this.

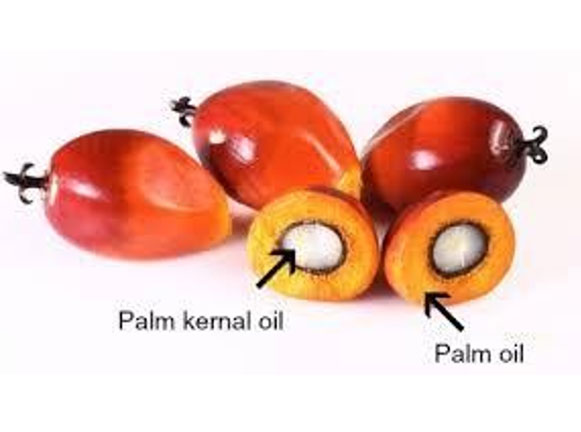

The industry will normally refer to something called Oleo chemicals which are derived from natural oils and fats e.g Palm Oil, Palm Kernel Oil. These oils are renewable sources but also biodegradable which means that they ensure environmentally friendly products. Crude fatty acids and Glycerol can be produced by a process called Hydrolysis which is basically high temp/pressure fat splitting methods. There is also a process worth mentioning called Alcohol sis as well as high temp/high pressure Hydrogenation to produce fatty alcohols and fatty amines.

Without getting too technical we can consider that further chemical modifications we can produce numerous types of products that have a good commercial use e.g fatty acids and fatty acid derivatives can undergo a manufacturing process to be an essential part of soap, washing up liquids and cleaning products as well as cosmetics, dyestuffs, textiles and lubricants. There are of course so many applications where Oleo chemicals can be used but this is simply being mentioned in order to broaden our understanding regarding the current applications and the myriad of potential future applications. The list can go on ad infinitum.

Palm Oil is popular as a cooking oil for many people over the world. It also does not get people into religious arguments because it is acceptable to all religions.

The industry will normally refer to something called Oleo chemicals which are derived from natural oils and fats e.g Palm Oil, Palm Kernel Oil. These oils are renewable sources but also biodegradable which means that they ensure environmentally friendly products. Crude fatty acids and Glycerol can be produced by a process called Hydrolysis which is basically high temp/pressure fat splitting methods. There is also a process worth mentioning called Alcohol sis as well as high temp/high pressure Hydrogenation to produce fatty alcohols and fatty amines.

Without getting too technical we can consider that further chemical modifications we can produce numerous types of products that have a good commercial use e.g fatty acids and fatty acid derivatives can undergo a manufacturing process to be an essential part of soap, washing up liquids and cleaning products as well as cosmetics, dyestuffs, textiles and lubricants. There are of course so many applications where Oleo chemicals can be used but this is simply being mentioned in order to broaden our understanding regarding the current applications and the myriad of potential future applications. The list can go on ad infinitum.

Palm Oil is popular as a cooking oil for many people over the world. It also does not get people into religious arguments because it is acceptable to all religions.

OIL PALM PROCESS:

The process from picking the Oil Palm to how it gets into stores is quite fascinating for a Palm Oil enthusiast. The Palm Oil has to be extracted and this requires the use of a system that is familiar to process plant engineers. It firstly involves separating a grading process where the good fruits are separated from the bad (which are then discarded) since they are lower quality. The good fruits are then placed in a large conveyer system which leads to a splitter which is true to it's name because it literally splits the palm fruits into smaller pieces.

The split fruit is then carried by a conveyer system and it falls into large cages which are placed in a sterilizer to be heated at a high pressure in a similar way to a familiar steam cooker. The cages containing the sterilized fruits are then taken by a rail carriage transporter to be emptied using a tipper and conveyed to a rotating threshing drum to separate the fruit from the husks and to go through screw conveyers to enter Digesters and then a presser will press the oil out or rather the CPO (crude palm oil) and the oil will eventually end up in a clarifier and then be dried using a Vacuum Type Oil Dryer to minimize the water content in the Palm Oil.

It is a common practice for trucks to transport the CPO from a mill to refineries for further processing. At the receiving bay of the Palm Oil Refinery Truck unloading station the custody transfer process takes place. This means that the buyer is able to monitor the volume and water content of the delivery to ensure that it meets his specifications. This can be done manually or automatically using online quality monitors attached to the outlet pipes of the truck during delivery. The results might have an impact on the price per load since higher quality CPO is more useful to buyers.

The split fruit is then carried by a conveyer system and it falls into large cages which are placed in a sterilizer to be heated at a high pressure in a similar way to a familiar steam cooker. The cages containing the sterilized fruits are then taken by a rail carriage transporter to be emptied using a tipper and conveyed to a rotating threshing drum to separate the fruit from the husks and to go through screw conveyers to enter Digesters and then a presser will press the oil out or rather the CPO (crude palm oil) and the oil will eventually end up in a clarifier and then be dried using a Vacuum Type Oil Dryer to minimize the water content in the Palm Oil.

It is a common practice for trucks to transport the CPO from a mill to refineries for further processing. At the receiving bay of the Palm Oil Refinery Truck unloading station the custody transfer process takes place. This means that the buyer is able to monitor the volume and water content of the delivery to ensure that it meets his specifications. This can be done manually or automatically using online quality monitors attached to the outlet pipes of the truck during delivery. The results might have an impact on the price per load since higher quality CPO is more useful to buyers.

The CPO is then further refined by processes such as fractionation and separation. The impurities are removed and the palm oil is further filtered and bleached. The refining process also removes odors. Solid stearin and liquid olein fractions can be produced and then it is ready for the basis raw material that is used in many familiar palm oil products.